Description

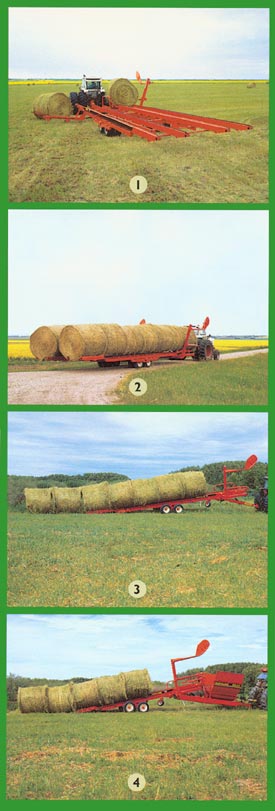

1. The Model 1400 has two bale forks for loading from either side.

All models have a standard 1/4 turn bale fork to automatically turn bales for non-stop loading from virtually any angle.

Each side of the Model 1400 is controlled independently so you can fill up one side before filling up the other.

Single row models come with a stabilizer wheel that automatically engages and retracts for increased stability on hilly terrain and along ditches.

2. Overall, Highline Bale Movers are faster, even when miles from home because you only need one tractor and one operator and you don’t need to stop and start while loading.

3. Unload without leaving the tractor.

Back the Bale Mover where you want the bales, tilt the bed, engage the conveyor chains and drive slowly forward.

Bales are stored in long, straight rows to minimize weathering damage.

4. Bales can be reloaded for further transporting or processing into Highline’s Bale Pro processors.

Reload by engaging the conveyor chains, and slowly backing into the row with the bed tilted – the conveyor chains carry the bales back up the rails.

Bale Mover | Model 1400 | Model 700 | Model 500 |

Configuration | double row | single row | single row |

Horsepower Required | 90 hp | 60 hp | 60 hp |

Hydraulic Outlets Required | 2 | 2 | 2 |

Capacity | 14 – 5′ bales | 7 – 5′ bales | 5 – 5′ bales |

Tires | 8 – 11L x 15, 12 ply | 4 – 11L x 15, 12 ply | 4 – 11L x 15, 12 ply |

Overall Length | 44′ | 42′ | 32′ |

Bed Length | 37′ | 37′ | 27′ |

Transport Width | 17′ | 8′ | 8′ |

Shipping Weight | 8500 lbs | 4500 lbs | 3200 lbs |